Production Process

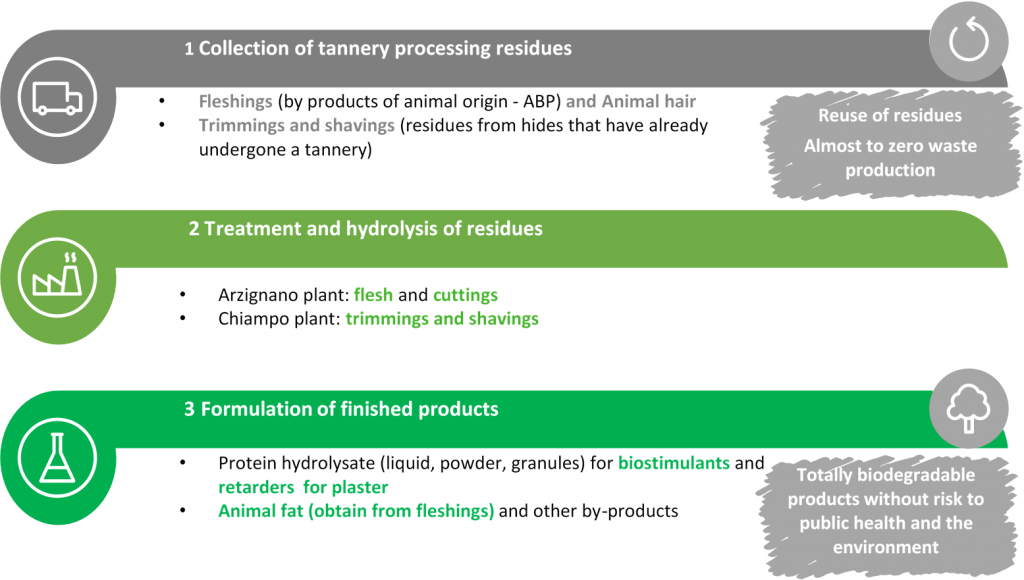

SICIT’s production process is divided into three distinct phases:

- Collection of tannery processing residues;

- Treatment phases and hydrolysis of residues;

- Formulation of finished products for the bio stimulants and plaster retarders sector.

SICIT obtains raw materials from tanneries, mainly in the Vicenza district and, secondarily, from Tuscany and other Italian and European production areas, to which it provides a paid service as an alternative to the cost of treatment and disposal in landfills or other production sites with higher disposal charges. This take-back service represents an opportunity for the tanning industry to sustainable management of residues. Otherwise, residues can be destined for disposal with a high impact on the environment. Through the Quality Control laboratory and the ABP take-back management teams (in Arzignano) and tanned residues (in Chiampo), SICIT monitors the quality and quantity of incoming raw materials on a daily basis in order to intercept potential trends and plan the take-back service with suppliers of incoming raw materials.

Compared to post-tanning residues, animal by-products are putrescible and, for this reason, must be processed within 48 hours after entering the plant, which makes it necessary to obtain supplies from tanning districts located at a short distance. Although there are no contractual obligations related to the collection of tannery residues, SICIT has established a stable and long-term relationship with the tanneries of the Vicenza district, which has led it to guarantee the supply of residues. Trimmings and shavings are not perishable and so SICIT evaluates retreats from tanneries according to its production needs and can more easily obtain supplies from other tanning districts both in Italy and abroad.

Raw materials undergo a process of treatment and hydrolysis (thermal process in an acid and/or alkaline environment) in order to extract amino acids and peptides from the protein matrix (collagen). This process is carried out in the two plants of SICIT, in Arzignano for the processing of animal by-products and in Chiampo for the processing of post-tanning residues. The treatment and hydrolysis phases generate the hydrolyzed protein that represent semi-finished products (so-called bases) for the next phase of preparation of the finished product. These protein hydrolysates – individually or mixed with each other and/or with other products of organic and/or inorganic origin – give rise to finished products, sold by SICIT in the B2B channel.

SICIT has tanks for the storage of hydrolyzed bases produced. This allows to have a potential warehouse volume suitable to reduce the business risk deriving from the impossibility to collect the tanning residues, in the months in which the sales volumes are higher than the volumes collected.

The hydrolyzed protein obtained from the hydrolysis process, which is in a liquid, dense and viscous form, undergoes further processing, on the basis of the formulations agreed with the customer, with the aim of associating further components to the amino acid and peptide base and/or modifying its physical state (formulation in powder, flakes or granules). The products thus obtained can be sold as such or packaged in industrial packaging and made available for sale to SICIT customers, who will sell them under their own brand. When the product is not sold unpackaged, it is packaged directly in SICIT’s plants in industrial packaging, i.e. tanks and drums of variable volume for liquid products or industrial bags for powdered products. The packaging of the product for marketing to the end user is the responsibility of the customers.