Product quality and safety

The health and safety of SICIT products has always been a central aspect of the way of doing business.

Sicit Chemitech S.p.A. Quality Control laboratory provides analytical support to the Group’s activities, controlling the risks that may impact on the ineffectiveness of the service. Right from the acceptance phase, the Quality Control laboratory carries out controls on incoming chemical products, semi-finished products during the production cycle and final products. It also ensures compliance with technical specifications and product quality standards, as well as the correctness of the production process and provides support to customers. Sicit Chemitech S.p.A. has adopted a quality management system in compliance with UNI EN ISO 9001:2015.

In 2019, Sicit Chemitech S.p.A. carried out the following controls:

| Controls | Number |

|---|---|

| Intermediate | 6,358 |

| Finished product | 17,698 |

| Environment | 6,149 |

| Research | 8,566 |

| External | 4,552 |

| Total | 65,366 |

| Certificates issued | 3,513 |

In compliance with the Quality Policy, the laboratory is commited to define, involving process managers, strategies for the continuous updating of technological innovation of monitoring and measurement resources, promoting the competence, awareness and involvement of personnel with internal and external training plans.

The traceability procedure used in plants makes it possible to identify every single batch of the final product that is specifically numbered, making it possible to trace the corresponding batch of raw material through the registers managed by the production department. In this way, complete traceability of the material and process is guaranteed. The traceability system not only provides the customer with detailed information on the product but also allows the prompt management of any non-conformities.

All complaints and reports from consumers are handled by the Commercial Department, while for analytical non-conformities or organoleptic aspects, the Quality Control Department is involved.

SICIT is constantly committed to providing an effective and timely response to its customers. During 2019 there were no episodes of non-compliance concerning impacts on the health and safety of products and services.

REACH Regulation

The “REACH” (Registration, Evaluation, Authorisation of Chemicals) Regulation regulates the registration, evaluation, authorization and restriction of chemicals in the European Union, providing, in particular, that manufacturers and suppliers of such substances must provide information on the risks posed by substances and how to handle them throughout the supply chain.

SICIT, in accordance with REACH Regulation, provides for the registration of new chemicals to the European Chemicals Agency (ECHA) with the aim of promoting the safe use of chemicals.

Innovation, Research and Development

Product and process innovation has been one of the main growth factors for SICIT in recent years and will be one of the strategic elements for its development in the future. Research and development activity concerns the product and process.

Product R&D

Product R&D is aimed at designing new products with high added value that meet customers’ needs and optimise raw material yields in terms of marginality and quality. The area carries out research into new formulations and raw materials, product improvement, sampling, preparation of instructions for use, production support and verification of product regulations, testing and validation.

The research and development activity related to the product is carried out for the chemical, chemical-physical and bacteriological control phases in the SICIT laboratories in collaboration with the Sicit Chemitech S.p.A. Quality Control laboratory. In particular:

- SICIT’s chemical-extractive laboratory for the development of formulations, both new and changes to formulations already made, both internally developed and defined by clients;

- the agronomic laboratory of SICIT, where the various phytotoxicity and efficacy tests are carried out;

- the quality control laboratory of SICIT Chemitech, in support of the previous ones.

The R&D function carried out independently basic and applied research activities.

Following this, the development of new products is carried out in close collaboration with the “Commercial” and “Operations” Functions in order to verify, from the very first design phases, the actual interest of customers in potential new products. Moreover, the close collaboration of the two functions enables to verify the purchase for sufficient volumes to justify the increase in complexity in the planning of production and purchase.

This activity is conducted by a team of seven people.

Process R&D

Process R&D is dedicated to the basic design phases and plant fine-tuning with laboratory tests and experiments with pilot plants, in order to increase efficiency and production yield, as well as to introduce new processes with consequent new commercial opportunities.

The area collaborates with the internal design technical office or with external technicians for the definition of the executive project of the production plants. Dedicated resources and laboratory technicians carry out the activity.

The development of new production processes is carried out in close cooperation with:

- the “Operations” and “Procurement” functions, in order to verify the actual industrialisation potential of the project and thus reduce the risk that the project will have to be abandoned after the initial development phases;

- the “Operations” and “Commercial” functions, to reduce the risk that any changes to production processes may cause substantial changes to the characteristics guaranteed to customers in the finished products;

- the “Environment” function, to ensure that the introduction of new processes complies with the regulations in force from time to time and thus reduce the risk of non-compliance.

SICIT started the construction of new laboratories at the Arzignano plant to improve research and quality control, which should be completed by the first quarter of 2021. This will make it possible to bring the three laboratories together in a single building adjacent to the management offices and to expand the R&D and Quality Control phases.

SICIT GROUP WINS THE “TECHNOLOGY AND INNOVATION” PRIZE

AT THE 2019 GREEN CARPET FASHION AWARDS

SICIT Group was awarded with the ʺTechnology and Innovationʺ prize at the Green Carpet Fashion Awards (“GCFAʺ), held yesterday in Milan. The event – which has an international resonance and has now reached its third edition – celebrates the sustainability goals achieved by the fashion and luxury industry worldwide.

The award confirms the Company’s commitment to sustainable development models: SICIT, forerunner of the circular economy, has been offering since the 1960s a service of strategic importance for the Vicenza district of the Chiampo valley – the most important in Italy for the tanning industry and one of the most important in the world – as it collects and transforms the residues of leather processing into high-added-value products for agriculture and industry, limiting the production of waste to almost zero. The bio stimulants and retarders produced by the company are totally biodegradable, without risks for the public health and the environment.

Supply chain

SICIT strives for maximum competitive advantage in purchasing processes, promoting criteria of conduct in relations with its suppliers based on mutual loyalty, transparency and collaboration.

With regard to procurement, a distinction must be made between suppliers of non-recycled materials (such as chemical products mixed with protein hydrolysate, packaging, etc.) and the so-called “suppliers of input raw materials”, those subjects, typically tanneries, who provide the “input raw materials” (animal by-products and other tanning residues). SICIT provides the take-back service, for a fee, of these “input raw materials”.

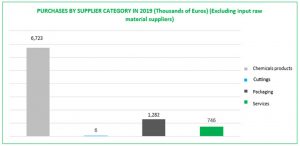

In 2019, SICIT counted 82 between suppliers and suppliers of input raw materials who served both production plants. 24 out of 82 are suppliers of chemical products, for which there is a cost of 6.7 million Euro. 9 out of 82 are packaging suppliers (1.2 million Euro) while 3 are services suppliers (for the collection and transport of materials from tanneries) for a cost of 0.7 million Euro. Purchases of cuttings* represent a small percentage of total purchases.

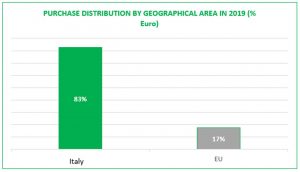

In 2019, over 80% of SICIT’s purchases (in value) were made by suppliers based in Italy.

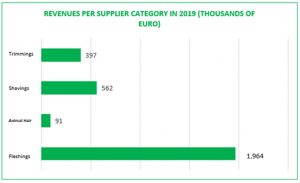

In 2019, SICIT collected waste material from the leather tanning process from 41 suppliers of input raw materials. The most significant category in economic terms, in 2019, was the category of suppliers of raw material input from flesh tanning, represented by 24 companies, for a revenue of 34% (1.9 million euros).

* Waste product from tanneries for which SICIT pays a purchase cost instead of receiving a price for the disposal service. The cuttings is supplied by 5 suppliers for a cost of 5,863 thousand Euros.